Order fulfillment efficiency no longer depends on speed alone, but depends on orchestration. High-performing fulfillment houses operate as coordinated systems where data flow, process logic, and execution discipline reinforce each other. When authorization, order intake, warehousing, quality check, packing logic, and logistics routing operate as one coherent chain, throughput rises while error rates fall. However, when any link remains manual, fragmented, or poorly governed, scaling exposes weaknesses quickly.

This article examines practical methods to improve fulfillment efficiency from a process, systems, and execution perspective.

Why does fulfillment efficiency depend on system structure rather than individual effort?

Many warehouses attempt to solve inefficiency by adding labor, but it fails once order volume rises beyond human coordination limits. Sustainable performance comes from architecture, rather than effort.

Before optimizing individual steps, you need structural alignment between data inputs, processing logic, and execution outputs. Modern fulfillment systems have already clearly proven the fact that automated order synchronization, centralized inventory logic, and integrated logistics management outperform fragmented workflows at every scale. Platforms supporting store authorization, automatic order intake, real-time freight calculation, and centralized order tracking show how architecture drives stability and speed.

How can inbound order processing be stabilized at higher volumes?

Once daily order volume exceeds a few hundred, manual processing introduces risk. At this moment, predictable intake behavior appears to be critical.

How does automated order synchronization reduce operational risk?

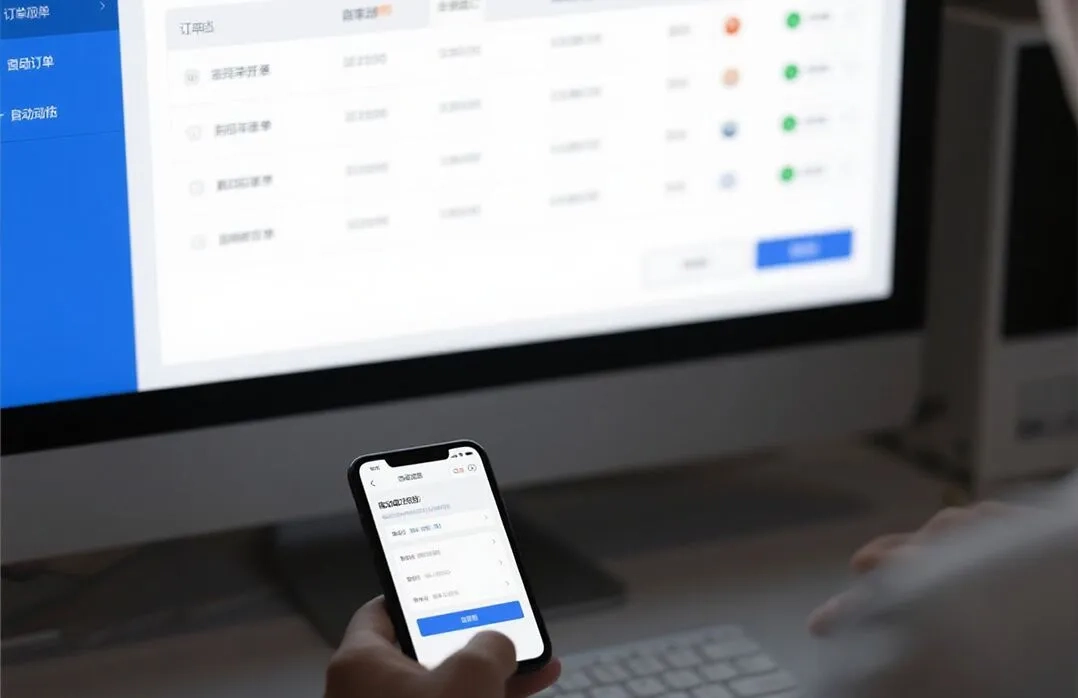

Systems that automatically synchronize orders after store authorization eliminate the lag between purchase and processing. Orders arrive in a unified queue instead of scattered channels, which prevents missed requests and delayed dispatch. Features such as automated order capture and structured order dashboards already demonstrate measurable gains in processing accuracy.

This is where solutions such as cumprimento automático become operationally relevant rather than marketing claims. Once order intake becomes deterministic instead of manual, fulfillment managers gain control over throughput instead of reacting to chaos.

How does structured data import improve batch handling?

Not all clients operate through direct platform authorization. Some rely on batch order submission. Structured CSV/Excel import mechanisms that automatically calculate totals and generate tracking references reduce clerical load while maintaining consistency across thousands of SKUs, which preserves scalability even when integration maturity varies between clients.

Why does warehousing discipline define long-term fulfillment performance?

Warehousing is the foundation of reliability. Fast order intake means little if inventory logic remains weak.

How does centralized cloud warehousing reduce inventory friction?

One-stop cloud warehousing models already illustrate how structured storage environments improve operational clarity. These models combine safe storage conditions, digital inventory systems, and professional warehouse operations, allowing sellers to send goods into a unified environment instead of fragmented storage locations, thereby removing blind spots in stock availability and preventing duplicated inventory decisions.

From a fulfillment house perspective, it means better slotting discipline, fewer picking conflicts, and predictable stock accuracy.

How do package splitting and consolidation improve workflow flexibility?

Modern order structures are no longer uniform, and bundles, mixed SKUs, and customized sets are increasingly common. Services that support package splitting and consolidation enable operational flexibility without breaking standard workflows, preventing exceptions from overwhelming standard operating procedures.

When such logic is embedded in the process instead of improvised on the floor, fulfillment teams preserve speed without sacrificing precision.

How does quality check influence efficiency rather than slow it down?

Some operations treat quality inspection as a bottleneck. In reality, weak quality check creates far greater downstream inefficiency.

How do inbound and outbound inspection reduce costly rework?

Well-structured fulfillment environments perform inspection both before goods enter storage and before dispatch. Products are carefully inspected at both stages, supported by cross-departmental quality responsibility.

This discipline prevents error propagation. A mislabeled SKU or defective item that reaches the customer generates returns, support tickets, reshipments, and reputation damage. Strong quality check shortens the total cost per order even if it adds seconds to handling time.

How does customized packaging improve process clarity?

Fewer micro-decisions lead to higher sustained throughput.

Customized packaging is often discussed as a branding feature. Operationally, it also improves efficiency. When packaging formats, labels, and inserts follow predefined standards, pickers and packers make fewer decisions per order. Customized packaging has been considered to be a part of structured fulfillment workflows.

How can logistics configuration reduce hidden inefficiencies?

Many fulfillment houses focus internally while ignoring the outbound logistics structure. This is a mistake.

How does integrated logistics management reduce processing latency?

When tracking visibility is unified, exception handling becomes proactive rather than reactive.

Systems that include built-in logistics management allow teams to view tracking records in real time and select transport options based on time and cost constraints. This eliminates the need for staff to manually reconcile data across external tools, emails, and spreadsheets.

How does multi-channel delivery support stabilizing international fulfillment?

Support for multiple transportation methods and global delivery routing contributes to the stability of international fulfillment because this capability can prevent cross-border sellers from the bottlenecks of fulfillment when certain routes degrade or peak seasons shift capacity. A fulfillment house that cannot dynamically adjust logistics pathways eventually becomes the limiting factor in its own growth.

Who builds systems that align technology, process, and execution?

At higher maturity levels, fulfillment efficiency depends less on individual tools and more on ecosystem design.

LZ Dropshipping has built our own service model around integrated sourcing, inventory storage, order processing, and global delivery rather than fragmented task outsourcing. Our operational model reflects many of the structural features described earlier, including centralized warehousing logic, automated order synchronization, systematic quality inspection, customized packing workflows, and logistics coordination.

What distinguishes our platform is not isolated features but coherence. Instead of asking clients to assemble our own patchwork of tools, our system architecture emphasizes full-chain continuity: goods move from sourcing to storage, from storage to processing, and from processing to delivery under one operational logic. For fulfillment managers and cross-border operators, it reduces friction between departments and minimizes the invisible coordination cost that usually erodes margins.

Notably, solutions such as ordenando um clic demonstrate how synchronization between listing, pricing logic, and order execution can compress entire operational cycles into predictable flows rather than manual sequences.

How should performance optimization be approached in daily operations?

Even strong systems degrade without discipline. Operational excellence requires ongoing tuning.

How can processing data reveal hidden inefficiencies?

Order timestamps, pick duration, pack duration, and dispatch latency form a performance fingerprint. When these metrics drift, the cause is not always labor, but process ambiguity, layout inefficiency, or tool fragmentation. High-performing houses review these signals weekly rather than quarterly.

How does standardization protect performance during scaling?

Growth exposes weaknesses in informal practices. Teams that document pick logic, packaging rules, escalation flows, and exception handling maintain stability as volume rises. Systems already designed around structured services scale far more smoothly than ad-hoc operations.

How should continuous improvement be structured for long-term efficiency?

Fulfillment efficiency is not a project, but a permanent operating posture.

How do periodic workflow audits prevent silent performance erosion?

Processes drift over time, and small manual workarounds accumulate. Quarterly operational reviews that examine queue times, exception rates, and error types help identify where informal practices are replacing formal systems.

How does disciplined system evolution preserve competitiveness?

Platforms that already integrate automation, warehousing logic, quality check, and logistics provide a blueprint for how fulfillment operations evolve—not by adding complexity, but by removing ambiguity.

Operations that follow this trajectory tend to remain stable even when order volume multiplies.

FAQ

Q1: Does automation always improve fulfillment efficiency?

A: Only when automation aligns with process logic. Automating fragmented workflows often accelerates errors. Automation built on structured order intake, inventory control, and inspection protocols consistently improves performance.

Q2: Is warehousing optimization more important than faster packing speed?

A: Yes. Layout, inventory clarity, and slotting discipline typically influence throughput more than individual packing speed. Strong warehousing logic reduces motion waste across the entire operation.

Q3: How frequently should fulfillment processes be reviewed?

A: Operational data should be reviewed weekly, while deeper workflow audits should occur at least quarterly. This prevents gradual drift from formal processes toward inefficient workarounds.